Introduction

Imagine your car gliding smoothly around corners, maintaining perfect balance even on sharp turns. That balance is no accident—it’s largely thanks to the sway bar and sway bar links, often overlooked heroes of your vehicle’s suspension.

These components are like the nervous system in your body: subtle, yet crucial. Without them, handling becomes unpredictable, turns feel dangerous, and your vehicle’s stability is compromised. A secret layer of engineering that influences performance, safety, and driving confidence is revealed when one understands sway bars.

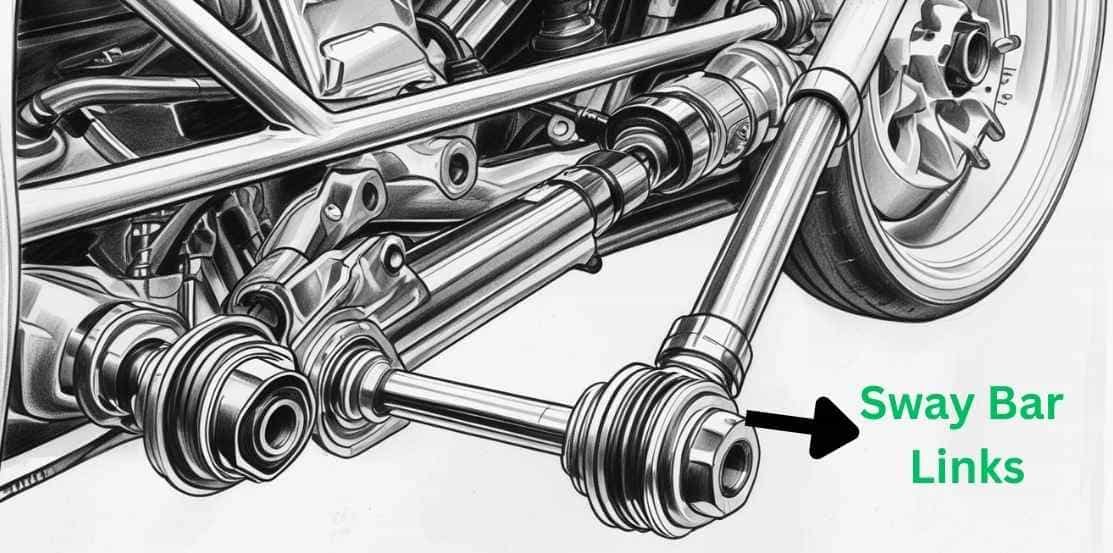

What is a Sway Bar and Sway Bar Link?

A metal rod that joins a car’s left and right wheels is called a sway bar or anti-roll bar.Its main objective is to minimize body roll when cornering. Think of it as a bridge that keeps your car balanced, transferring force from one side to the other to prevent tipping.

FOR MORE BLOG PLS VISIT : BLOKEP INDO

The suspension parts of the car are connected to the sway bar by sway bar links. They function as connections or hinges, enabling the sway bar to dynamically twist, flex, and steady the vehicle. Without functional links, the sway bar cannot do its job effectively, leading to unstable handling.

Origin and Engineering Background

In the 1920s and 1930s, when automakers were experimenting with suspension systems to increase vehicle stability, sway bars were first introduced. Early cars leaned excessively during turns, making sharp cornering risky. Engineers developed the anti-roll bar to mechanically link the suspension, distributing weight and reducing tilt.

The sway bar links, a smaller but equally critical part, evolved as vehicles became more complex. Designers needed a flexible connector that could handle dynamic forces without failure. Over decades, the materials, geometry, and strength of sway bars and links have been refined, leading to modern performance and safety standards.

Real-World Applications

While sway bars are most commonly associated with cars, the concept has influenced other sectors:

- Automotive Industry: Improves stability, cornering, and safety. Used in SUVs, sports cars, and trucks.

- Off-road vehicles: Better traction and flexibility across uneven terrain are made possible by adjustable sway bars.

- Motorsport: Race cars use tuned sway bars links for optimal handling and performance.

- Bicycles and Motorbikes: Some high-performance designs use stabilizing links inspired by automotive sway bars.

- Engineering & Robotics: The principle of anti-roll or force distribution is applied in robotics for balance and stability.

In essence, the sway bar concept has transcended automotive use, influencing designs wherever balance and stability are crucial.

How Sway Bars Differ from Other Suspension Components

| Feature | Sway Bar / Links | Shock Absorbers / Struts | Springs |

| Purpose | Reduce body roll | Absorb road impact | Support vehicle weight |

| Connection | Connects left-right wheels | Connect to chassis & wheels | Mounted between frame & axle |

| Movement Control | Stabilizes cornering | Dampens vertical motion | Provides spring tension |

| Adjustment Possibility | Adjustable in performance cars | Usually fixed | Fixed or variable coil rates |

Unlike shocks or springs, sway bars do not absorb road bumps; they specifically handle lateral stability, keeping the vehicle level and responsive.

Future Implications and Innovations

As vehicles become more advanced, sway bar technology is evolving:

- Electronic Sway Bars: Active devices that automatically modify stiffness in response to road conditions.

- Lightweight Materials: Carbon fiber and high-strength alloys reduce weight while maintaining strength.

- Integrated Suspension Systems: Combining sway bars with adaptive shocks and sensors for AI-driven handling.

Ethics & Safety Considerations: Proper maintenance is critical. Accidents may result from a malfunctioning sway bar links. As vehicles advance, engineers must balance innovation with reliability to prevent failures.

Best Practices – How to Maintain and Upgrade Sway Bars

- Regular Inspection: Check sway bar links for wear, rust, or damage every 10,000–15,000 miles.

- Lubrication: To minimize squeaking, some sway bar Links bushings require sporadic lubrication.

- Use High-Quality Parts: OEM or premium aftermarket parts have a longer lifespan.

- Upgrade for Performance: Adjustable or thicker sway bars links improve cornering for sportier vehicles.

- Replace When Needed: Don’t ignore symptoms like clunking noises or unstable handling.

How to Change and Fix Sway Bar Links

Tools Needed: Socket wrench, jack stands, penetrating oil, replacement links.

Step-by-Step Guide:

- Lift the vehicle safely using a jack and secure it on jack stands.

- Locate the link that connects the suspension and sway bar.

- Apply penetrating oil to bolts to loosen rusted parts.

- Remove the old sway bar link using the appropriate socket size.

- Install the new link, ensuring tight and secure connections.

- To verify handling stability, lower the car and do a test drive.

This process can often be done at home, but if you’re uncomfortable, a professional mechanic ensures safety.

Common Symptoms of a Bad Sway Bar Links

- Clunking or rattling noises over bumps

- Increased body roll when cornering

- Loose or unstable steering feel

- Uneven tire wear

- Vehicle leaning excessively in turns

Promptly addressing these symptoms guarantees safety and stops additional suspension damage.

Sway Bar Link Replacement Cost

Replacement costs vary depending on the vehicle model and parts used:

- Standard link: $25–$75 per link

- Labor: $50–$150 depending on mechanic and region

- Total: $75–$225 for a full replacement per axle

Costs can be lower if DIY installation is possible. Upgrading to performance links may cost more but can enhance handling.

Sway Bar Links & Accessories

Accessories include:

- Upgraded bushings for reduced noise

- Adjustable links for performance tuning

- Reinforced sway bars for heavy-duty or off-road vehicles

- Anti-corrosion coatings for longevity

Using the right accessories can improve the durability and performance of your suspension system.

Sway Bar End Link

The point of connection between the sway bar and the suspension or control arm is known as the sway bar end link.

- Transfers force to reduce body roll

- Needs proper torque and alignment

- Can wear out faster in high-performance or off-road conditions

Replacing worn end links is essential to maintain vehicle stability.

FAQs – Sway Bar and Sway Bar Links

1. What do sway bar links do?

They assist balance the vehicle and lessen body roll during turns by attaching the sway bar to the suspension.

2. What is a sway bar link?

A small rod or connector that joins the sway bar to the vehicle’s suspension components.

3. Bad sway bar link symptoms?

Clunking noises, poor handling, excessive body roll, or uneven tire wear.

4. Sway bar link replacement cost?

Depending on labor and parts, each axle typically costs $75 to $225.

5. How to change and fix sway bar links?

Lift the vehicle, remove the old link, install the new one, and ensure secure torque on all bolts.

Conclusion – Why Sway Bars Are Unsung Heroes

Sway bars and their links may seem small, but they dramatically affect vehicle safety, handling, and driving confidence. They are the hidden layer of engineering that balances forces, just as a tightrope walker uses a pole to stay steady.

From everyday commuters to off-road adventurers and motorsport enthusiasts, understanding, maintaining, and upgrading sway bars ensures safety, performance, and long-term vehicle health.

By learning about sway bars, their links, symptoms, replacement costs, and maintenance, drivers gain not just mechanical knowledge but an appreciation for the intricate systems that make modern driving safe and enjoyable.